Ore Milling Equipment

Ore milling equipment is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc

Feature of ore milling equipment

- The separator can be adjusted very easily.

- High Pressure Suspension Mill meets the requirement of national dust-dump standard.

- The multi-class seals are adopted to keep the grinding equipment tightly closed.

- Size of final product can be 0.613mm (30mesh) –0.033mm (425mesh). Some can reach the fineness of 0.013mm (1000 mesh).

- Compared with other mills, its capacity increases by 10%-20% under the same power condition, and compression force of rollers to material improve 800-1200kgf under the force of high-pressure spring.

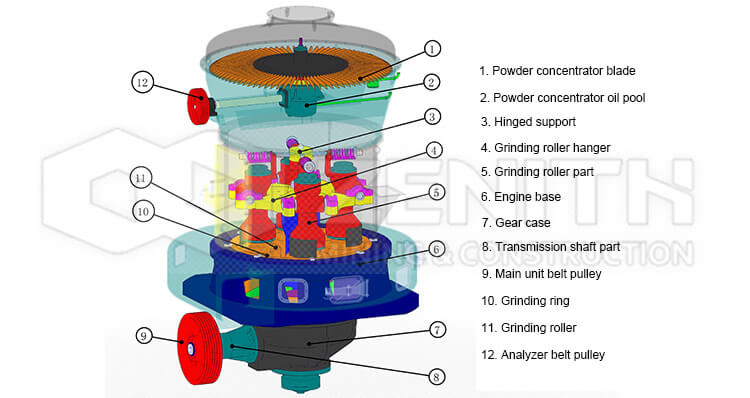

Working principle of ore milling equipment

When entering grinding chamber, the raw materials are shoveled up by the shovels and grinded between the rollers and ring; the materials after grinding are brought into the separator along with the air from the blower, and the qualified fine powder became final products and come into the cyclone powder collector, the other unqualified powder fall down to be re-grinded. The circular air returns back to the blower that the above process will be repeated, and the remaining air enters the bag filter in order to protect the environment.

The development trend of ore milling equipment

The development trend of grinding equipment is as follows: large-scale grinding machine; development of high efficiency energy-saving ball mill; development of fine grinding and ultra-fine grinding equipment. Because of the great change in the diameter of the mill, the grinding process will also change a little, and the diameter of the mill will be too large, which will bring some new problems to the production. For example, the decrease of the speed, easy to cause the ball impact smaller, grinding effect, ball and ore contact less, dead ball charge increases rapidly, the unit volume decline, the power consumption of grinding products is high, so the diameter of ball mill design can not exceed a certain range.